A Bright Future Ahead

Portable Spectral Services Announces Exciting Management Transition

Automated micro-X-ray fluorescence (micro XRF) technology emerges as a powerful tool to rapidly and accurately capture the mineralogy of rock chip, RC and AC samples. It provides mining professionals with the rapid, accurate, and actionable mineralogical data needed to make strategic decisions and providing significant advantages for exploration and mining companies.

Micro XRF is an advanced analytical technique that uses focused X-ray beams to excite atoms in a sample. This causes them to emit characteristic secondary (or fluorescent) X-rays. This fluorescence is characteristic of the elemental composition of the minerals, allowing for precise identification and quantification. The automation aspect involves sophisticated software and robotics that enable high-throughput analysis, minimal human intervention, and real-time data processing.

Speed & Efficiency: Comprehensive mineral data in days not weeks.

Accurate & Detailed: Quantitative data on mineral content of sample.

Versatile & Applicable: Evaluated across multiple geological settings

Non-Destructive: Valuable samples remain intact for further testing

Cost-Effective: Automation enables us to pass on cost savings

Comprehensive Data: Insights into mineralogical variations and ore body characteristics.

Better Decision-Making: Identify and target high-value mineral zones more effectively.

Streamlined Workflow: Automation reduces the time between sample collection and data acquisition.

Optimization of Mining Operations: Real-time mineralogical data, enhancing recovery and reducing waste.

Innovative Edge: Early adopters leveraging cutting-edge tools to stay ahead of competitors.

The purpose of the technique is to get a general sense of the RC sample mineralogy; the representativeness of the sample is crucial for obtaining accurate and meaningful results. Routine chips collected at rig in chip trays are ideal for analysis.

A single, well-chosen chip will suffice, depending on:

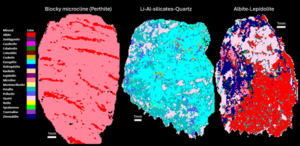

Analysis begins with AC RC chips that are selected to characterize the mineralogy that best represents the individual meter (image 1). The automated micro-XRF then processes and scans the samples, resulting in an elemental and mineral map being created. Image 2 shows the mineral map from automated micro XRF analysis.

The mineral map becomes a valuable tool for insights into the mineralogy of the RC chips selected. As seen in image 3, geological settings, host rocks and alterations can be determined. This can then be interrogated a step further to show alteration and mineralization of the individual RC chips with the accompanying data (image 4, 5).

It is with this critical information that overall RC chip mineralogy can be reliably updated (image 6). Mineral maps and accompanying data can be used to create even more detailed mineralogy. This is extremely useful in seeing an overview of the hole overall, but also in the details often missed by similar techniques. Images 7-9 show a highlighted selection of detailed mineralogy found in this mineral map scan from the automated micro XRF.

Analysis begins again with the RC chips being selected to characterize the mineralogy that best represents the individual meter. The automated micro-XRF then processes and scans the samples, resulting in an elemental and mineral map being created. Image 10 shows the mineral map from automated micro XRF analysis. The detail that is captured via the micro-XRF scan results means that grain details can be studied on individual chips. As image 11 shows, this can make all the difference when observing the mineralogy across the samples selected. Accompanying mineral data (image 12) can show the amount of mineral in each RC sample.

Automated micro XRF technology represents a significant advancement in the field of mineralogical analysis, offering rapid, accurate, and cost-effective solutions for exploration and mining companies.

By adopting this technology, companies can gain deeper insights into ore body composition, streamline their operations, and maintain a competitive edge in the market. Embracing automated micro XRF technology is not just a step forward in analytical capabilities but a strategic move towards total OBK and more efficient and profitable mining ventures.

Portable Spectral Services Announces Exciting Management Transition

Our tool introduces uXRF (micro-X-ray fluorescence) scanning technology to RC chip analysis, enabling rapid, non-destructive, and quantitative analysis of major, minor, and trace mineral phases.

Automated micro-X-ray fluorescence (micro XRF) technology emerges as a powerful tool to rapidly and accurately capture the mineralogy of rock chip, RC and AC samples.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.