A Bright Future Ahead

Portable Spectral Services Announces Exciting Management Transition

In the highly competitive and technologically driven field of mineral exploration and mining, precision and efficiency are paramount. The advent of automated micro-x-ray fluorescence (micro XRF) technology is revolutionizing the way mining companies gain insights into ore bodies. This automated technology provides detailed, accurate, and real-time data that drives informed decision-making. This article delves into the application of automated micro-XRF in mineral exploration and mining, highlighting its importance for acquiring comprehensive ore body knowledge.

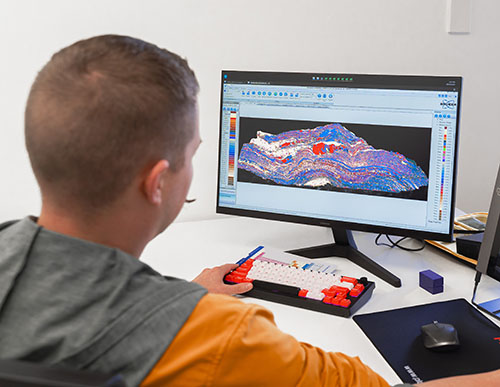

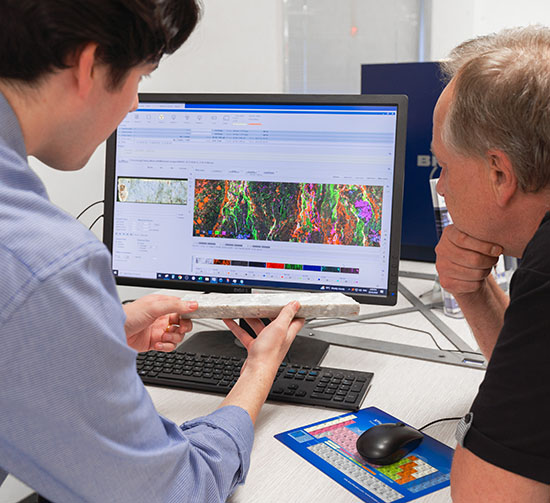

Micro-XRF is an advanced analytical technique that uses focused X-ray beams to excite atoms in a sample, causing them to emit characteristic secondary (or fluorescent) X-rays. These emitted X-rays are then analyzed to determine the elemental composition and distribution within the sample. Automation enhances this process by integrating robotic systems and sophisticated software, enabling high-throughput, continuous analysis with minimal human intervention.

Automated Micro XRF systems can rapidly analyze large quantities of samples, providing detailed geochemical profiles essential for identifying mineral deposits. This high-throughput capability is particularly beneficial during early-stage exploration when large amounts of samples need to be screened efficiently.

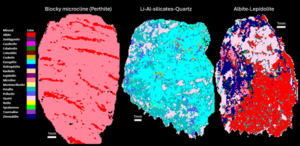

Automation allows for the creation of high-resolution maps that depict the spatial distribution of minerals within an ore body. These detailed maps are crucial for understanding geology, ore body geometry, mineral associations, and alteration zones, informing more accurate resource estimates and extraction stratagies.

Maintaining consistent ore quality is critical in mining operations. Automated micro XRF offers real-time, on-site monitoring of ore grades and mineralogy enabling immediate adjustments in mining strategies to optimize resource extraction and reduce waste, thus enhancing overall operational efficiency.

During exploration drilling automated micro XRF provides instant feedback on drill chip and core samples as results are available within hours of starting analysis. This rapid turnaround accelerates decision-making processes, which ultimately optimize drilling campaigns and reduces associated costs by ensuring that current drilling targets are in the most promising areas.

Automated micro XRF systems can continuously monitor the environmental impact of mining activities, such as the dispersion of potentially harmful elements. This ensures compliance with environmental regulations and supports the development of effective remediation strategies.

Automated micro XRF systems offer exceptional precision in elemental analysis, delivering high-resolution data crucial for understanding the intricate composition of ore bodies. This precise information is vital for accurate resource estimation and efficient mine planning.

The automation of micro XRF significantly reduces the time required for sample analysis. Real-time data acquisition and high-throughput capabilities streamline exploration and mining processes, leading to faster project timelines and reduced operational costs.

Automation minimizes human intervention, thereby reducing the risk of errors associated with manual sample handling and analysis. Consistent and reliable results are essential for making critical decisions with confidence.

By enabling precise targeting of mineral deposits, automated micro XRF reduces the environmental footprint of mining operations. It minimizes unnecessary drilling and excavation, promoting more sustainable mining practices and improving the industry’s overall environmental stewardship.

The detailed insights provided by automated micro XRF systems allow for a comprehensive understanding of ore bodies. This knowledge is instrumental in developing effective mining strategies, optimizing resource extraction, and enhancing the economic viability of mining projects.

While the initial investment in automated micro XRF systems may be substantial, the long-term benefits. These benefits include reduced labour costs, faster analysis times, and improved resource management, which result in significant cost savings.

In the technologically advanced and fast-paced world of mineral exploration and mining, the integration of automated micro XRF technology is crucial for acquiring detailed and comprehensive ore body knowledge. Its precision, efficiency, and ability to provide real-time data make it an indispensable tool for modern mining operations.

Companies that adopt automated micro XRF will not only gain a competitive edge but also enhance their capacity to discover and efficiently extract the valuable resources that drive our global economy. As the industry continues to innovate, automated micro XRF will play a pivotal role in shaping the future of ore body analysis and mineral extraction.

Want to see the automated micro-XRF laboratory for yourself? Book a demo today!

Portable Spectral Services Announces Exciting Management Transition

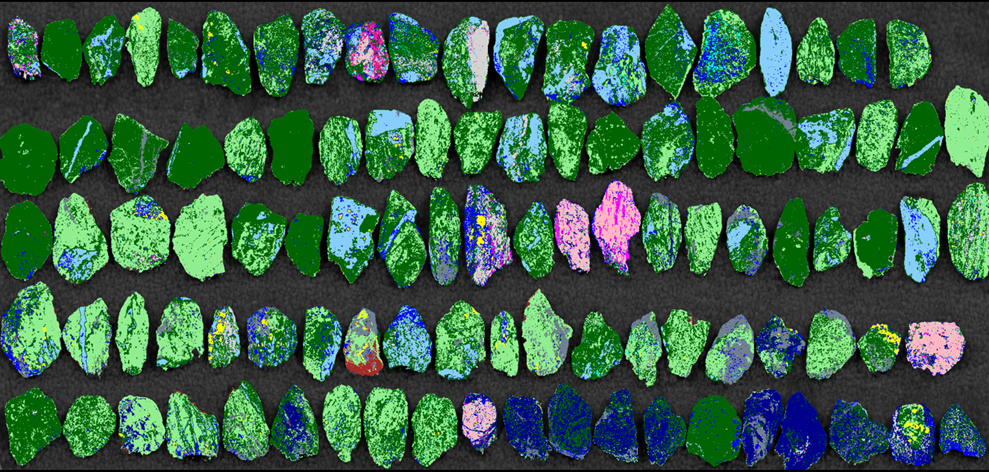

Our tool introduces uXRF (micro-X-ray fluorescence) scanning technology to RC chip analysis, enabling rapid, non-destructive, and quantitative analysis of major, minor, and trace mineral phases.

Automated micro-X-ray fluorescence (micro XRF) technology emerges as a powerful tool to rapidly and accurately capture the mineralogy of rock chip, RC and AC samples.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.