A Bright Future Ahead

Portable Spectral Services Announces Exciting Management Transition

All new portable XRF instruments are tested for radiation leakages before they leave the factory; this is known as their radiation profile. The instrument is then issued with a ‘Compliance Certificate’ from the factory. It is a statutory requirement that compliance certificates are issued in most states of Australia.

After using your instrument for a few years, travelling out bush and on aircraft with the XRF, how do you know if it is still safe? Is the shielding inside the casing of the instrument still in place?

Portable Spectral Services can conduct Radiation Profiling of Portable XRF instruments. We check the radiation profile and leakage of the instruments and ascertain through a series of tests whether the interlocks are operating according to the manufacturers design and specification. PSS offer radiation profiling for all brands of XRF instruments. Our testing is done to government standards, with a report being provided upon completion.

It is a statutory requirement that Compliance Certificates are issued in some states of Australia. Checking that all the safety measures contained within the instrument’s hardware and software are in good working order thereby ensuring safe shutdown in case of malfunction. A Radiation Profile is included in this service to provide you the Certificate of Compliance. PSS are only registered in some states to provide this certificate.

As X-rays are emitted from the portable XRF, regular compliance testing is required, which vary from state to state within Australia. Failure to comply with these regulations can result in hefty fines from the radiation authority in that state. To find out if you are required to have a Compliance Certificate, contact your states radiation authority.

Keeping up to date with the servicing of your Portable XRF Analyser is highly important. Similarly to a car, your instrument needs to be regularly serviced to ensure it is in its best working condition. Yearly services on handheld XRF analysers are recommended as a preventative maintenance process in order to extend the life of the instrument and check for any ongoing issues and the calibration and make sure the instrument is performing optimally. This is regardless of whether the instrument has been used every day or sitting idle for the year.

A Condition Report is designed to provide the user with information on the current state of a Portable XRF instruments stability, accuracy, precision, software status and physical condition.

Our inhouse technical staff can work with you to troubleshoot any issues you are having with your instruments. We offer assessments of older Portable XRF instruments, along with recommendations on how to proceed with your instrument. Whether it be a quotation for repair (Bruker), or to assist in purchasing a new instrument that suits your needs, we are here to help.

If you would like more information on any of the services we offer, get in contact with us today.

*Dependant on Make/Model

Portable Spectral Services Announces Exciting Management Transition

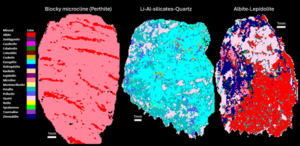

Our tool introduces uXRF (micro-X-ray fluorescence) scanning technology to RC chip analysis, enabling rapid, non-destructive, and quantitative analysis of major, minor, and trace mineral phases.

Automated micro-X-ray fluorescence (micro XRF) technology emerges as a powerful tool to rapidly and accurately capture the mineralogy of rock chip, RC and AC samples.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.

Findings of an ongoing regional evaluation study over concealed Proterozoic lithologies known to host magmatic nickel sulphides with potential to host other base-metal, gold and rare earth elements (“REE”) systems within the Fraser Range, Western Australia.